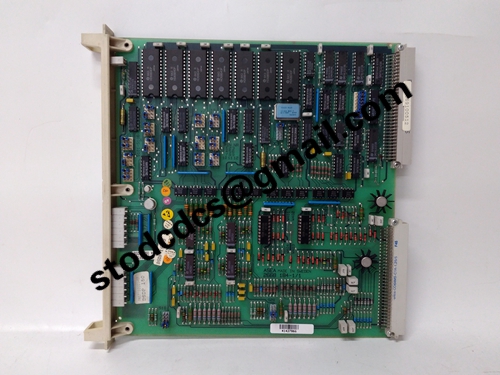

Gasonics A95-056-01 Endpoint Detector

Product manual:

product overview

Gasonics A95-056-01 is an endpoint detector used in semiconductor manufacturing equipment, primarily for monitoring the process completion time during plasma processing or etching. It analyzes the optical changes in the plasma reaction gas to determine whether the cleaning or etching has reached the preset conditions, in order to optimize the process control accuracy.

Technical parameters (brief)

Type: Optical Endpoint Detector

Working principle: Based on changes in plasma emission spectra

Installation method: Integrated into the plasma processing chamber

Application equipment: Suitable for Gasonics Aura series plasma cleaning equipment

Application scenarios

Photoresist removal (Plasma Ashing)

In the semiconductor wafer manufacturing process, it is used to identify whether the photoresist stripping is completed and avoid excessive processing.

Dry etching end monitoring

In silicon wafer etching, detectors can monitor changes in plasma reaction products to determine whether the process has reached the set depth or morphology.

Plasma cleaning process control

In the wafer cleaning process, accurately determining the cleaning endpoint reduces equipment contamination and residue.

Gasonics plasma equipment matching

Commonly used in Aura 1000, Aura 2000, Aura 3010 and other models as original or replacement parts.

Product advantages

Strong real-time performance: Quickly determine the endpoint through spectral changes, improving equipment operating efficiency

High precision: can effectively control cleaning or etching time, avoiding wafer damage

Good compatibility: compatible with multiple Gasonics plasma processing systems

Easy to maintain: modular design for easy replacement and maintenance

Product details picture:

A95-056-01

More related products:

DS200LDCCH1AKA Digital Expansion Module

5SHX1445H0001Lowvoltapowersupplychip

6ES7307-1KA02-0AA0powersupplymodule