Details

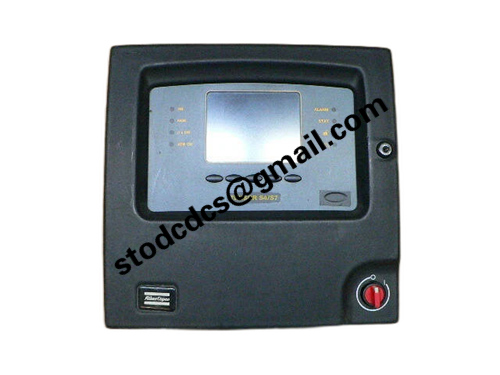

ATLAS COPCO PF300-G-HW Power Focus Controller

Product manual:

1、 Product Overview

ATLAS COPCO PF300-G-HW is one of the early fastening controllers in the Power Focus 300 series,

DC electric torque tool used to control Atlas Copco.

The controller adopts a modular design and has basic torque/angle control functions,

Suitable for low to medium complexity tightening process applications, especially for primary automation or semi-automatic assembly lines.

2、 Main functions briefly

Control mode: Supports torque control, angle control, and step program control

Adaptation tool: Supports connection with Atlas Copco Tensor series tools (such as Tensor ST, ES, etc.)

Communication capability: Equipped with standard I/O control interfaces, some models support serial or fieldbus modules

Data capability: equipped with basic tightening data recording, result output, and error alarm functions

Interface: Button operation or external control panel, supporting program switching and status display

3、 Application Fields

1. Manufacturing of automotive parts

Suitable for non assembly stations, such as seat frames, door panels, interior, headlight assembly and other processes

Meet the needs of small batch and modular assembly

Can be deployed in manual workstations or simple rhythm lines

2. Household appliances and electronic equipment industry

Applied to the bolt tightening process of washing machines, refrigerators, air conditioning compressors, etc

Support standardized tightening operations for electrical control boxes, motor housings, and wiring terminals

3. Light industry assembly line

Precision control for small industrial equipment and instrument assembly

Support single channel control in multi-channel operation mode (applicable to fixture control systems)

4. Tool testing and maintenance station

Can be used as a testing platform for new tool debugging or after-sales maintenance evaluation

Support loading specified programs to simulate actual tightening scenarios

5. Engineering Technology Development Laboratory

Used for parameter setting and tightening strategy verification in the process of process development

Provide a stable output and controllable parameter testing environment

Product details picture:

PF300-G-HW

More related products:

YOKOGAWANFAI841-S00Input/outputmodule

YAMATAKEEST0240Z05WBX00Touchscreen

More product recommendations:

UFC760BE143 inverter high-voltage board