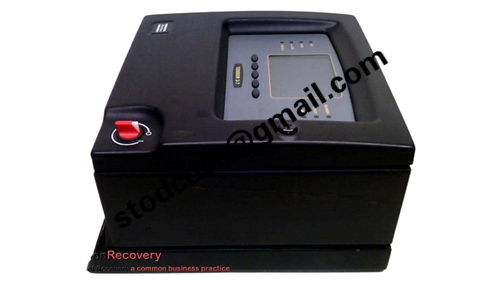

Atlas Copco PF3107-G-DN-HW Controller Driver Device

Brand:Atlas Copco

Model:PF3107-G-DN-HW

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

Atlas Copco PF3107-G-DN-HW Controller Driver Device

Product manual:

1、 Product Overview

Atlas Copco PF3107-G-DN-HW

It is an intelligent power tool controller drive device for the medium to high torque range in the Power Focus 3100 series.

It is used to drive and control the Atlas Copco Tensor series electric tightening tools, achieving high-precision and high consistency torque and angle control,

Simultaneously possessing industrial bus communication and multi program control capabilities, it is widely used in modern industrial assembly lines.

Model analysis:

PF3107: PF3100 series, suitable for medium power tools

G: Advanced control version, supporting more complex processes and communication

DN: Built in DeviceNet communication module, compatible with Allen Bradley, Omron and other PLCs

HW: Standard hardware configuration

2、 Technical parameters

Project parameters

Control mode: torque control/angle control/angle monitoring/multi-stage control

Power input AC 100-240V, 50/60Hz, adaptive

Communication protocols DeviceNet (built-in), Ethernet RS232、 Digital I/O

Support tools such as Tensor ST, SL, EBL, ETX, STR, and other electric tools in the torque range

Maximum number of supported programs ≥ 255

Data recording supports local data storage, curve collection, and traceability functions

Program switching supports remote signal switching/barcode scanner/workstation recognition

3、 Typical application areas

1. Automotive manufacturing and final assembly

Bolt tightening station for powertrain, chassis, and steering system

Linkage with PLC and MES to achieve quality traceability and workstation binding

2. New energy vehicles and power battery industry

Application of high consistency torque control in battery casing, electronic control system, and electric drive assembly

Collaborate with robots to perform automatic tightening operations

3. Industrial automation and robot assembly station

Integrate with the robotic arm end to perform multi angle/multi-stage tightening tasks

Automatic program selection triggered by image recognition or workstation positioning

4. Construction machinery and rail transit

Provide multi-stage composite control for the tightening process of heavy-duty connection parts

Stable and reliable continuous operation in high-intensity environments

Product details picture:

PF3107-G-DN-HW

More related products:

Elmo G-TUB30480ERSS0 Ethernet servo driver

6ES7314-1AE01-0AB0CentralProcessingUnit

JetterJM-204-480-JC310-S1servodrive

More product recommendations:

ASEA 57310256-BA circuit board