Details

Gasonics 90-1079 Fault Detection Module

Product manual:

product overview

Gasonics 90-1079 is a fault detection module specifically designed for plasma cleaning equipment, mainly used to monitor equipment operation status, detect system abnormalities,

Technical parameters (typical characteristics)

Module type: Electronic fault detection module

Detection content: power status, signal interruption, sensor failure, vacuum/air pressure abnormality, etc

Interface type: Communicate with the main control board or PLC through parallel/serial signals

Applicable equipment: Gasonics Aura 1000/2000 plasma cleaning system, etc

Application scenarios

Self diagnosis of plasma cleaning system

Real time monitoring of various process signals inside the cavity, once abnormalities are detected, the system will trigger an alarm or stop processing to protect the wafer from damage.

Process monitoring and protection

Continuously monitor the operational status of key components such as power supply, gas controller, RF generator, etc.

Fault isolation and alarm prompt

When the system detects that parameters such as air pressure, voltage, or temperature deviate from the normal range, issuing an alarm can help quickly locate the fault point.

Product advantages

Improving equipment safety: potential risks can be detected in a timely manner and processes can be suspended to prevent equipment damage

Modular design: easy to replace and maintain, suitable for long-term operating environments

Accurate diagnosis: In conjunction with the main control system, it can provide detailed reports of abnormal areas, which helps improve operational efficiency

Strong adaptability: compatible with multiple Gasonics systems and supports customized maintenance solutions

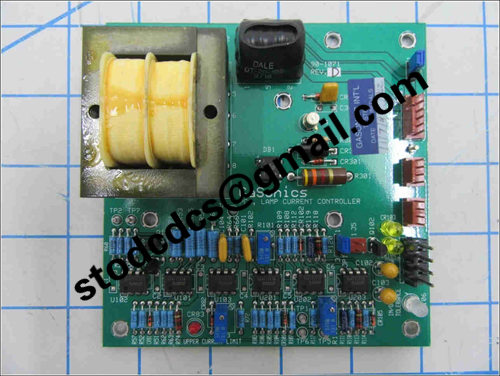

Product details picture:

90-1079

More related products:

GE 336A4940CSP16 Interface module