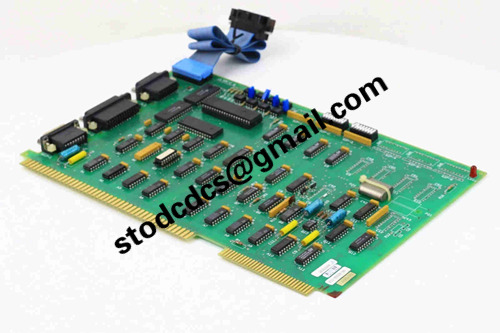

GIDINGS&LEWIS 411-80029-86 Controller Module Components

Brand:GIDDINGS & LEWIS

Model:411-80029-86

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

GIDINGS&LEWIS 411-80029-86 Controller Module Components

Product manual:

GIDDINGS&LEWIS 411-80029-86 Controller Module Components

1、 Product Overview

The GIDDINGS&LEWIS 411-80029-86 controller module component is a core control unit used in industrial automation and numerical control systems,

Used to manage and coordinate the operation of CPUs, I/O modules, servo drives, and other external devices.

This module component provides high-performance computing and real-time control capabilities, supports complex motion control, logic processing, and data communication, and is a key control core for CNC machine tools and automation equipment.

2、 Technical parameters (typical indicators, specific subject to physical object)

Module type: Controller module component

Processing capability: Supports multi axis motion control and real-time data processing

Interface type:

Modular slot bus interface

Supports multiple I/O, servo drive, and encoder interfaces

Input/Output: Digital Input/Output, Analog Input/Output

Communication protocol: Industrial bus communication (such as RS-232/RS-485, expandable fieldbus interface)

Power supply mode: DC 24V/5V provided by the rack power supply

Working environment: Industrial grade temperature and anti vibration design

Status indication: LED display module running, error, and communication status

Protection Function: Overvoltage, Overcurrent, and Short Circuit Protection

3、 Application scenarios

CNC machine tool

As the core control unit of the machine tool, it realizes multi axis coordinated motion, tool path control, and machining program execution.

Automatic production line

Manage various servo drives, sensors, and actuators on the production line to achieve automated process control.

robot system

Control the joints of the robotic arm, coordinate multi axis movements, and achieve high-precision positioning and trajectory control.

Testing and experimental equipment

Execute complex experimental sequences or testing procedures to ensure real-time data collection and control.

process control system

Perform logical control, data collection, and motion management in industrial systems such as chemical, packaging, and textile industries.

Product details picture:

411-80029-86

More related products:

6ES7315-2AF01-0AB0CPUprocessor

More product recommendations:

ASEA DSQC108 controller backplane