GIDINGS&LEWIS 501-04309-01 Dual Servo Drive Board

Brand:GIDDINGS & LEWIS

Model:501-04309-01

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

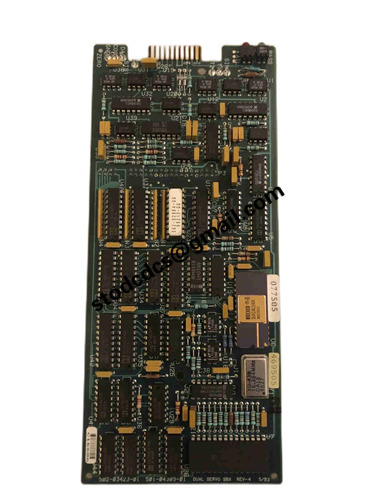

GIDINGS&LEWIS 501-04309-01 Dual Servo Drive Board

Product manual:

GIDINGS&LEWIS 501-04309-01 Dual Servo Drive Board

Product Overview

GIDINGS&LEWIS 501-04309-01 dual servo drive board is an execution module in industrial automation systems,

Used to drive two servo motors simultaneously, achieving precise speed, position, and torque control.

The drive board receives command signals from the main control system and outputs synchronous control signals to two servo motors,

Widely used in multi axis machine tools, robot systems, and multi axis linkage control of automated production lines.

Technical parameters (typical characteristics, actual values need to refer to official materials)

Control functions: closed-loop position control, speed control, and torque control

Number of channels: Dual channels, capable of driving two servo motors simultaneously

Input signal: Supports digital and analog command input

Output capability: Suitable for multiple specifications of servo motors, supporting continuous operation and short-term overload

Feedback interface: Supports position/velocity feedback devices such as encoders or rotary transformers

Dynamic performance: High speed response, ensuring precise control of multi axis linkage

Protection function: overcurrent, overvoltage, overheating, and short circuit protection

Installation method: Modular board design, easy to insert into system racks or control units

Environmental adaptability: Industrial grade design, resistant to high temperature, vibration, and electromagnetic interference

Application scenarios

Numerical Control Machine Tool (CNC)

Drive dual feed shafts or main and secondary shafts to achieve multi axis synchronous machining and high-precision operation.

Automatic production line

Synchronize the control of two executing devices, such as conveying, assembling, or testing mechanisms, to improve production efficiency.

robot system

Drive two joint servo motors to achieve precise motion of dual axis linkage.

Multi axis motion platform

Realize dual axis synchronous control in industrial handling, cutting or welding equipment to improve machining accuracy.

Process control industry

Control dual actuators in continuous production systems such as metallurgy, chemical engineering, and papermaking to achieve precise adjustment.

Product details picture:

501-04309-01

More related products:

1SAP11100R0260 Terminal Base

1SAP140500R3260 Programmable Converter

FOXBORO RH922VU output communication module

More product recommendations:

EMERSON 1000554 module card

WOODWARD 5501-470 Servo speed governor

7ML52020EA0 Ultrasonic level meter