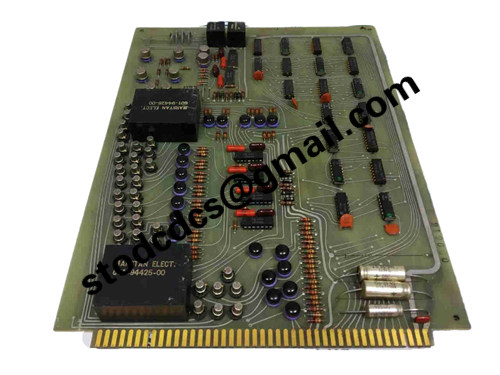

GIDINGS&LEWIS 502-02425-01 Decoding Generator Module

Brand:GIDDINGS & LEWIS

Model:502-02425-01

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

GIDINGS&LEWIS 502-02425-01 Decoding Generator Module

Product manual:

Product Overview

Giddings&Lewis 502-02425-01 is a decoding generator module in the PiC series control system,

Used to convert the position or velocity information of rotating machinery into digital signals for use in control systems.

It receives signals from encoders or rotation sensors and processes them through internal decoding circuits,

Output precise position information or velocity data to the controller to achieve high-precision motion control.

Product Features

High precision signal decoding

Supports incremental encoder and absolute encoder signal input.

Convert the motion of rotating machinery into digital signals to ensure accurate and reliable position and velocity data.

Multi channel processing capability

It can simultaneously process multiple encoder signals to achieve data acquisition in multi axis systems.

Adapt to complex multi axis motion control requirements.

Electrical isolation and protection

There is photoelectric isolation between input and output to improve anti-interference ability.

Built in overcurrent and short-circuit protection to prevent module or controller damage.

Industrial adaptability

Anti vibration and anti impact design, suitable for machine tools and industrial automation environments.

EMC has strong anti-interference ability, ensuring stable signal transmission.

Status indication and convenient maintenance

The LED indicator light displays the working status and signal processing of the module.

Modular design, convenient for installation, debugging, and on-site replacement.

Application field

Numerical Control Machine Tool: Collecting the rotational position and speed information of the spindle or feed axis to achieve closed-loop control.

Multi axis automation system: processes multiple encoder signals to achieve multi axis linkage and interpolation control.

Industrial automation production line: Collect sensor or rotating equipment data to ensure precise production line actions.

Precision machining and testing equipment: providing high-resolution position and velocity data, supporting precision operations and measurements.

Equipment monitoring and data collection: Real time collection of rotating machinery status to provide data support for system diagnosis and optimization.

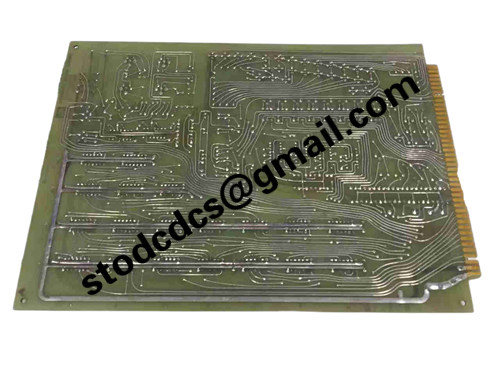

Product details picture:

502-02425-01

More related products:

6ES7312-5AC00-0AB0CentralProcessingUnit

6ES7315-2AF01-0AB0CPUprocessor

More product recommendations:

ASEA DSQC108 controller backplane