Details

GIDINGS&LEWIS 502-02815-01 Encoder Module

Product manual:

GIDINGS&LEWIS 502-02815-01 Encoder Module

Product Overview

The Giddings&Lewis 502-02815-01 encoder module is a feedback signal processing module used in CNC machine tools and automation systems.

It is mainly used to receive position or velocity signals output by rotary encoder sensors,

Technical Features

High precision signal analysis: Processing incremental or absolute position signals from rotary encoders to ensure accurate feedback.

Closed loop control support: In conjunction with servo drives or execution control boards, achieve high-speed and high-precision closed-loop control.

Multi channel support: Multiple encoders can be connected simultaneously to achieve multi axis monitoring.

Modular design: easy to install, replace, and expand the system.

Industrial environment adaptability: anti-interference, vibration resistant, suitable for heavy-duty machine tool environments.

Application field

CNC boring and milling machines

Provide precise position and speed feedback for axes such as spindle, worktable, and tool holder to achieve high-precision machining.

Vertical lathe and milling composite center

Coordinate multi axis actions to achieve complex part machining and multi process linkage.

Automatic production line

Used for precise position monitoring of robotic arms or multi axis execution units to ensure action synchronization.

Machine tool transformation and upgrading

In the numerical control transformation of old equipment, providing encoder signal interfaces to improve motion control accuracy.

Robots and precision mechanical equipment

Support motion feedback for high-precision robotic arms, automated assembly, or precision machining equipment.

Product advantages

High precision and high stability: ensuring the positioning accuracy and motion stability of the axis.

Strong reliability: closed-loop feedback and anti-interference design, suitable for complex industrial environments.

Good scalability: It can support multi axis and multi encoder access, meeting the requirements of complex systems.

Easy to maintain: modular structure for quick replacement and system debugging.

Improve production efficiency: optimize feedback and motion control, reduce processing errors, and enhance production efficiency.

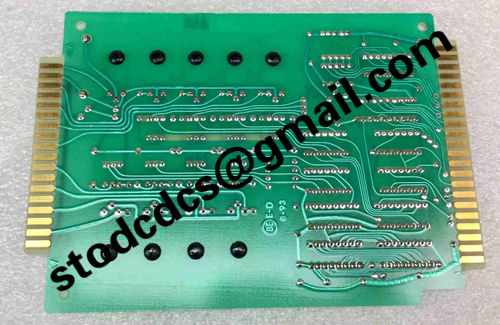

Product details picture:

502-02815-01

More related products:

CONDOR HCAA60W-A Industrial Linear Power Supply

Foxboro RH914XS Redundant Output Module

REXROTH VT-HNC100-1-22/W-08-0-0 Digital Axis Controller

More product recommendations:

Rexroth BTV04.2GN-FW Servo drive

DS3800DFXA1B1C Gas turbine electrical module

IS420UCSBH1A Gas turbine module