Details

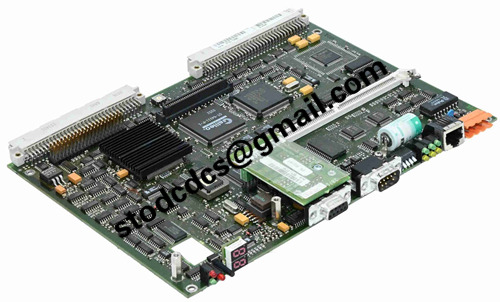

KEBA CU312 central processing module

Product manual:

Product Overview:

KEBA CU312 is the central processing module (CPU module) in the KEBA KeControl series,

Used for controlling the core task processing and communication coordination in automation systems.

This module utilizes high-speed processors, real-time operating systems, and rich communication interfaces,

Provide integrated platform support for machine control, motion control, human-computer interface interaction, etc.

CU312 is a medium performance level main control unit commonly used in fields such as medium-sized injection molding equipment, automation units, and packaging machinery.

Technical parameters:

Processor type: Embedded industrial CPU (32-bit)

Main frequency: about 300 MHz (specific version slightly different)

Memory configuration:

Program memory: Flash Memory (typically 32MB or above)

Operating memory: SDRAM, typically 64MB

Operating system: KEBA real-time operating system or Linux RT version

Communication interface:

1 x Ethernet interface

1 x System bus interface (connected to I/O or axis control module)

Expandable CAN, RS232, USB interfaces (specific configuration models)

Installation method: slot or DIN rail installation

Power supply requirement: 24V DC (powered through backplane)

Working temperature: 0 ° C to+55 ° C

Module size: Standard control rack width for easy integration into control cabinets

Application areas:

1. Injection molding equipment (KePlast system)

Control key process flows such as mold locking, injection molding, pressure holding, and mold opening.

Realize temperature control closed-loop, pressure monitoring and action synchronization.

2. Packaging Machinery

Control the molding, sealing, film feeding, and cutting actions.

Integrate with visual systems or tension control systems to achieve flexible packaging processes.

3. Automatic assembly and transmission line

Coordinate the running rhythm of multiple workstations, control equipment such as cylinders, motors, sensors, etc.

Provide data collection, alarm processing, and system synchronization control.

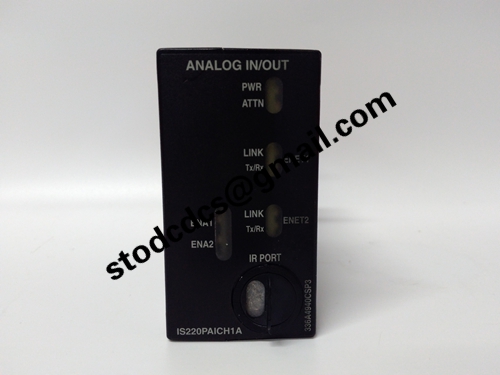

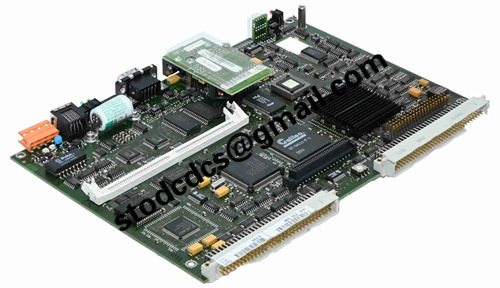

Product details picture:

CU312

More related products:

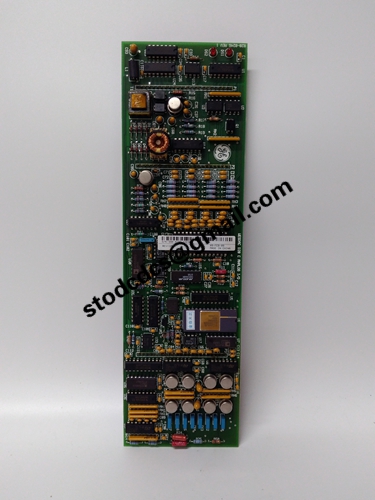

DSAI130A3BSE018292R1analoginputboard

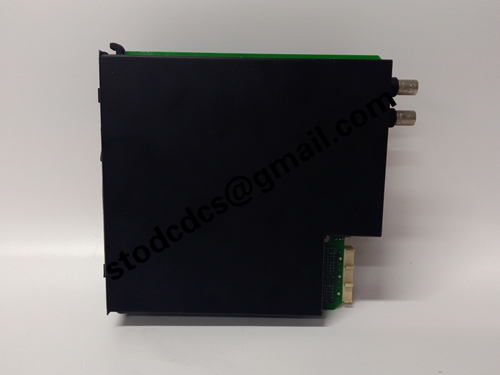

6ES7312-5BE03-0AB0LogicControllerModule

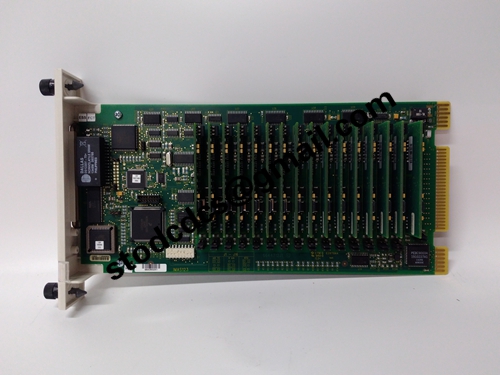

GE 336A4940CSP16 Interface module

More product recommendations:

AMAT 0190-11415 Digital Input Module