Details

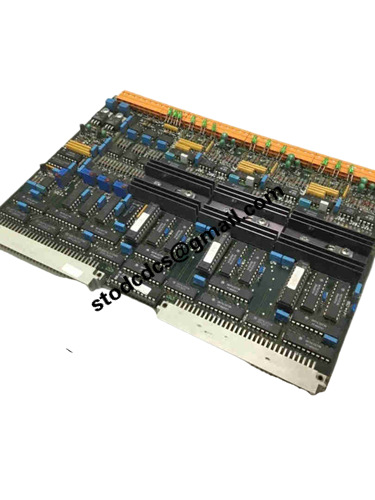

KEBA E-3-ACU-INC circuit board

Product manual:

Product Overview:

KEBA E-3-ACU-INC is an incremental encoder signal processing board in KEBA automation systems,

Used for receiving and parsing external incremental encoder signals (such as A/B/Z channels),

And convert it into a position signal or velocity feedback signal that the controller can recognize.

This module is often used as a key interface in motion control systems and is particularly suitable for high-precision applications that require closed-loop feedback.

Technical parameters:

Function type: Encoder interface circuit board

Supporting encoder types: incremental encoder (incremental rotary or linear encoder)

Channel support:

A. B orthogonal signal channel

Z (zero position) reference signal channel

Input signal level:

5V TTL/RS422 differential signal (standard)

Maximum input frequency:

Up to 1 MHz (depending on the processing capability of the encoder and controller)

Output interface:

Directly connected to the KEBA main control module or motion control card

Electrical isolation: It has photoelectric isolation between the input signal and the motherboard

Working voltage:

Usually 5V DC or 24V DC (powered by the system)

Onboard indicator light: LED status indicator (signal normal/fault)

Installation method: Rack mounted plug-in board installation or fixed on the backplane motherboard

Adaptation system: KeMotion, KeDrive, KeControl control architecture

Application areas:

1. Servo motor position/speed closed-loop control

Receive the output signal of the servo encoder and provide real-time feedback to the axis control module.

2. Linear motor and slide table system control

Capture feedback from linear encoders to achieve precise displacement control.

3. Robot motion monitoring and path correction

Obtain the deviation between the actual position and the commanded position to improve trajectory tracking accuracy.

4. High speed synchronization system for packaging, printing, labeling, etc

Read feedback from the driven shaft encoder to achieve multi axis synchronization and phase compensation.

5. Measurement and detection system

Used in high-precision measurement applications to detect position, angle, or movement distance.

Product details picture:

E-3-ACU-INC

More related products:

DS200SIOCG1AEA Analog Output Module

More product recommendations:

ASEA E-31709 Robot Circuit Board