Details

KEBA T40-001 robot teaching pendant

Product manual:

Product Overview:

KEBA T40-001 is a portable human-computer interaction device launched by KEBA,

Commonly used for teaching, debugging, and operating industrial robots and automation equipment. This teaching pendant has a compact and lightweight design,

Integrated touch display, function buttons, and safety control components (such as emergency stop and enable switches),

It is an important tool for robot programming and on-site debugging in automated production lines.

Technical parameters:

Display screen: 5.7-inch color TFT LCD display screen

Resolution: 640 × 480 (VGA)

Touch mode: resistive touch screen, supports glove operation

Key layout: 10-20 programmable function keys

Safety device:

Red emergency stop button (emergency stop)

Three stage enable switch

Connection method: Communicate with the main controller through industrial connectors or customized data cables

Cable length: Standard configuration of 5 meters, customizable extension

Shell protection: dustproof, oil proof, and resistant to industrial environmental interference

Weight: Approximately 1-1.5 kg, suitable for long-term handheld operation

Applicable systems: compatible with KEBA KeControl control platform, partially integrated robot systems (such as packaging lines, assembly robots)

Application areas:

1. Robot teaching and path programming

Guide the robot to complete point teaching through touch and button guidance.

Support fine pose adjustment and interpolation trajectory setting.

2. Debugging of automation equipment

Applied to manual operation control during the debugging stage of transmission lines, welding workstations, assembly modules, etc.

Real time monitoring of sensor inputs and device status.

3. Human machine interface operation and parameter setting

As a control panel, adjust device operating parameters, start or stop automation processes.

Support on-site modification of control logic parameters to improve flexible production capacity.

4. System maintenance and fault diagnosis

Easy for maintenance personnel to read alarm information, view device logs, and perform manual testing.

When an abnormality occurs in the device, the control actuator can be manually intervened.

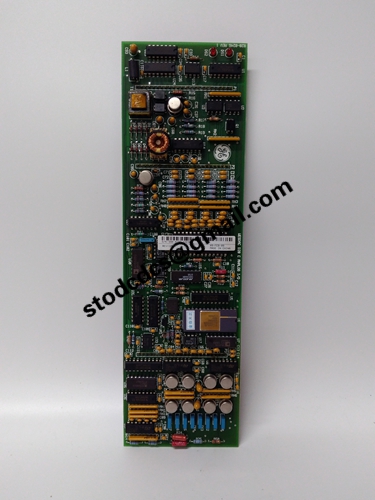

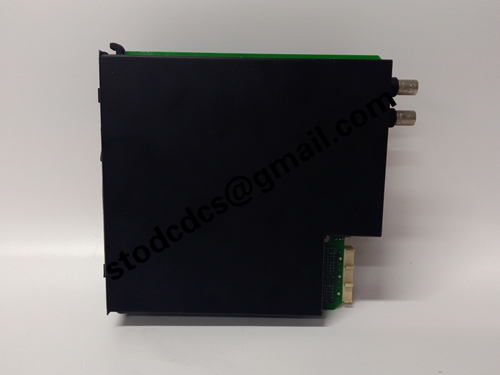

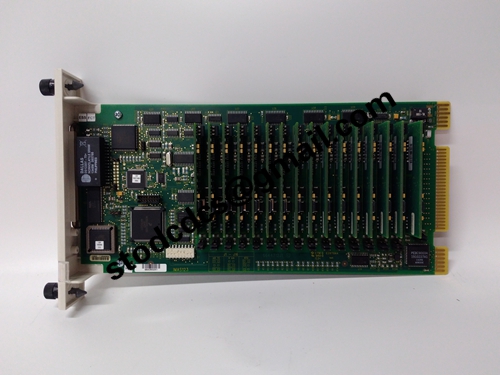

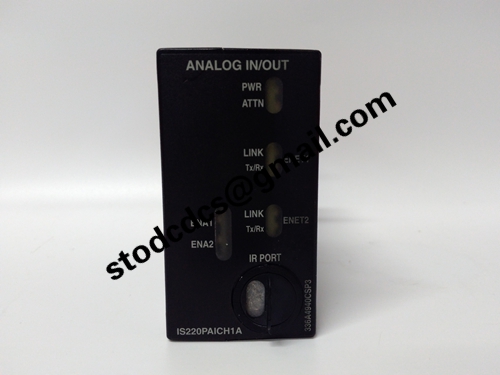

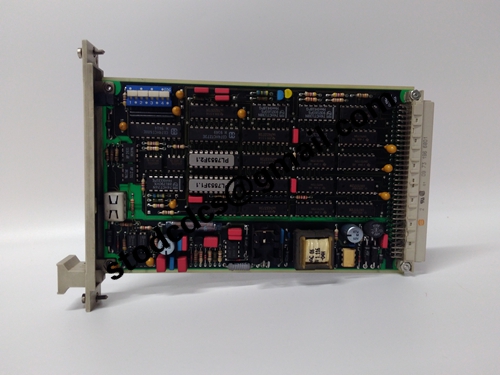

Product details picture:

T40-001

More related products:

6ES7312-5AC00-0AB0CentralProcessingUnit

6ES7315-2AF01-0AB0CPUprocessor

More product recommendations:

Kollmorgen 6SM37M-6000 servo motor