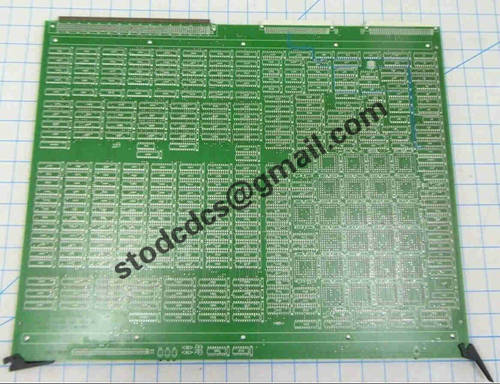

KLA Tencor 710-655651-20 Image Sensor Board Component

Brand:KLA-Tencor

Model:710-655651-20

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

KLA Tencor 710-655651-20 Image Sensor Board Component

Product manual:

KLA Tencor 710-655651-20 Image Sensor Board Component

product overview

KLA Tencor 710-655651-20 is an image sensor board component used in high-end wafer inspection and metrology equipment,

Its core function is to receive, convert, amplify, and preliminarily process image signals collected through optical systems.

Core functions

Image signal acquisition and conversion

Receive reflected or transmitted image signals from optical systems,

And convert it into an electrical signal through an image sensor.

Analog to Digital Conversion (ADC)

Convert the analog signal output by the image sensor into digital image data,

Facilitating subsequent image processing and analysis.

FEATURES

Project Description

Sensor type: High sensitivity CCD or CMOS

Image resolution supports up to several million pixels (depending on the model)

Sampling accuracy 12 bit or higher ADC

High speed serial digital transmission interface for data interface, such as LVDS or customized backplane interface

Layout form: Multi layer PCB board, compact integrated optoelectronic and control circuits

Electromagnetic interference suppression with built-in filtering and grounding design to ensure signal integrity

Working temperature range: 0 ° C to 50 ° C, suitable for clean room environment

application area

The KLA Tencor image sensor board is widely used in multiple key visual inspection processes in wafer manufacturing:

Optical Defect Inspection

Collecting surface images of wafers for detecting small defects such as particles, scratches, and pits.

Line width and structure measurement (CD Metrology)

Combining image processing algorithms to measure key parameters such as line width and edge roughness on wafers.

Overlay and Alignment

Image recognition of alignment marks on wafers to achieve precise photolithography alignment and interlayer matching.

Particle contamination inspection

Zooming in to inspect for particle contamination and foreign objects on the wafer can help improve product yield.

Product details picture:

More related products:

500BIO011MRB150005R1Jinvertercontrolunit

531X307LTBAKG1 power interface card module

More product recommendations:

AMAT 0190-66253 Communication Module