Details

TEL Tokyo Electron 11-14259-01 Thermal Plate

Product manual:

TEL Tokyo Electron 11-14259-01 Heater Plate

It is a heating module component specifically designed for semiconductor manufacturing equipment,

The main function is to uniformly heat the wafer in the process chamber to meet the precision requirements for temperature control under specific process conditions.

It is usually installed in reaction chambers, hot chucks, or other heat treatment components,

It is an important component of the equipment temperature control system.

1、 Basic Information

Product Model: 11-14259-01

Product Name: Heater Plate

Manufacturer: Tokyo Electron Ltd. (TEL)

Type: Process heating element, used for high-precision temperature control requirements

2、 Main functions

Heating function

Provide a uniform and stable heat source for the wafer or process area, and support setting different temperature ranges.

Temperature control interface

Equipped with temperature sensors such as thermocouples or RTDs, and combined with a temperature control system to achieve closed-loop control.

Thermal uniformity guarantee

Materials are usually made of high thermal conductivity metals or ceramics, with precise surface treatment to ensure uniform heat distribution.

Process support

Support high-temperature related process steps such as CVD, ALD, dry etching, annealing, preheating, etc.

3、 Typical application areas

CVD equipment (chemical vapor deposition)

Control the temperature of the reaction chamber to promote uniform deposition of chemical reactions.

Etching process module

Provide a heating environment to assist in the reaction efficiency during plasma etching process.

Wafer preheating/cooling station system

Preheat before wafer processing or maintain temperature balance in the pre cooling stage.

ALD (Atomic Layer Deposition) cavity

Realize constant or dynamic temperature control required for each deposition reaction step.

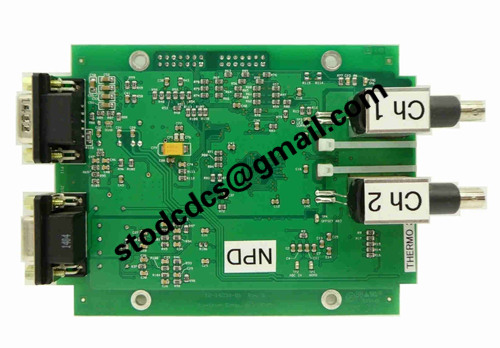

Product details picture:

11-14259-01

More related products:

ZYGOZMI-20028020-0211Multi-axisinterferometer

6ES7313-6CE00-0AB0CentralProcessingUnit

YokogawaYS1700-000A34Processcontrol