TEL Tokyo Electron 1B80-002391-11 Control Motherboard Card

Brand:TEL Tokyo Electron

Model:1B80-002391-11

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

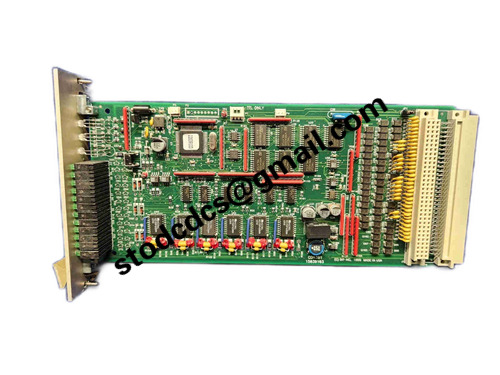

TEL Tokyo Electron 1B80-002391-11 Control Motherboard Card

Product manual:

TEL Tokyo Electron 1B80-002391-11 Control Main Board is a core control printed circuit board,

Mainly used for system level logic control, signal scheduling, submodule coordination, and process flow management in TEL semiconductor manufacturing equipment.

It is the central "control module" between multiple subsystems within the device, playing a critical role in the overall operation of the system.

1、 Basic Information

Product Name: Control Motherboard Card/Main Control Board

Product model: 1B80-002391-11

Manufacturer: Tokyo Electron Ltd. (TEL)

Functional classification: System level logic control, subsystem scheduling control

Typical location: Installed inside the main control electrical cabinet, rack, or control interface unit

2、 Main functions

Execution of equipment main control logic

Manage device startup initialization, process logic, shutdown sequence, etc;

Realize coordinated control of various sub modules (gas circuit, valve control, power supply, handling, etc.).

Interfaces

Integrate multiple communication interfaces (I/O bus, serial port, CAN, Ethernet, etc.) for connecting I/O boards, sensors, and driver units.

data acquisition and processing

Process feedback data from sensor boards, input cards, etc., and respond in real-time to control strategies.

Communicate with the upper system

Communicate with the host or engineering station, support formula download, parameter adjustment, log upload and other functions.

3、 Application device type (partial)

This controller card can be deployed in the following TEL device types:

Etcher (dry etching equipment)

Control core functions such as vacuum pump, plasma source, gas mixing module, etc.

CVD/ALD equipment

Manage subsystems such as temperature control zone, chemical source supply, and reaction chamber operation.

Coater/Developer (Photolithography and Development Equipment)

Coordinate wafer handling, rotation, development, heating and other functional units.

Transfer Robot System

Unified control of robotic arm motion trajectory, limit feedback, and claw movements.

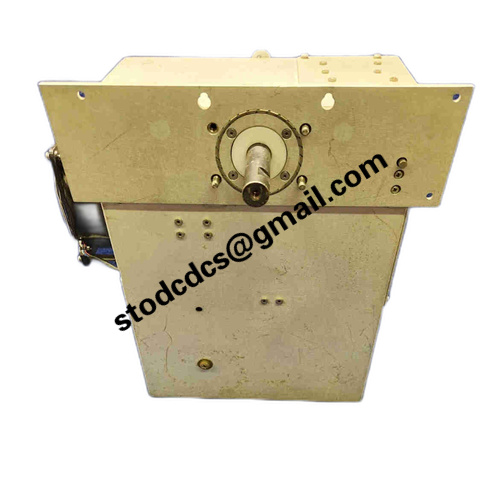

Product details picture:

1B80-002391-11

More related products:

AI8153BSE052604R1Analoginputmodule

DS200DCFBG1BNC Digital Controller Module