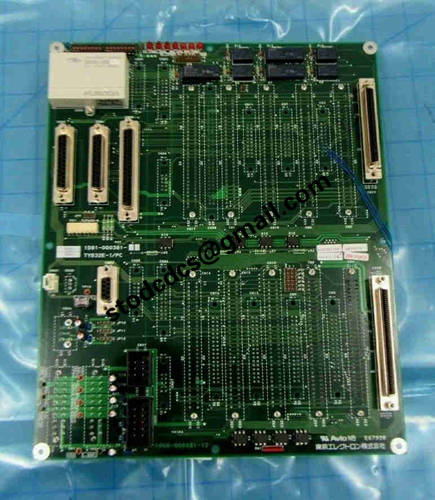

TEL Tokyo Electron 1D81-000381-16 Analog Input Electronic Module

Brand:TEL Tokyo Electron

Model:1D81-000381-16

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron 1D81-000381-16 Analog Input Electronic Module

Product manual:

TEL Tokyo Electron 1D81-000381-16 Analog Input Electronic Module

It is a high-precision analog signal acquisition unit used in Tokyo Electronics (TEL) semiconductor equipment,

The main function is to receive input data from various analog sensors such as temperature, pressure, flow, voltage/current signals, etc,

And convert it into a standard electrical signal that can be processed by the control system.

This module is one of the key electronic components for TEL devices to achieve high stability and precision process control.

1、 Product Overview

Project Content

Product Name Analog Input Module

Product Model 1D81-000381-16

Manufacturer Tokyo Electron Ltd

Application category data acquisition and signal interface module

2、 Core functions

Analog signal acquisition

Supports multi-channel analog input, usually used to read signals from temperature sensors (such as thermocouples, RTDs), pressure sensors, flow meters, and other devices;

It can collect industrial standard signals such as voltage (e.g. 0-10V) and current (e.g. 4-20mA).

A/D conversion and standardized output

Internally integrated high-precision analog-to-digital converter (ADC), which converts analog signals into digital signals in real-time;

The converted data can be directly read by the main control system to achieve real-time monitoring and control.

System integration and feedback

The collected data can be used as feedback input for closed-loop control systems, assisting in PID control, alarm judgment, and other functions;

Communicate with the TEL main control board (CPU module, logic processing module, etc.) to establish a complete data link.

3、 Typical application scenarios

temperature control

Collect real-time temperature data of the wafer heating stage, chamber wall, and isothermal zone of the fluid transport path.

Pressure/gas flow monitoring

Connect pressure transmitters, flow meters, and other sensors to monitor the operating status of process chambers and gas channels.

Process equipment status detection

Detect key process parameters such as cleaning solution level, power output voltage, and chemical gas concentration.

Product details picture:

1D81-000381-16

More related products:

AI8153BSE052604R1Analoginputmodule

DS200DCFBG1BNC Digital Controller Module