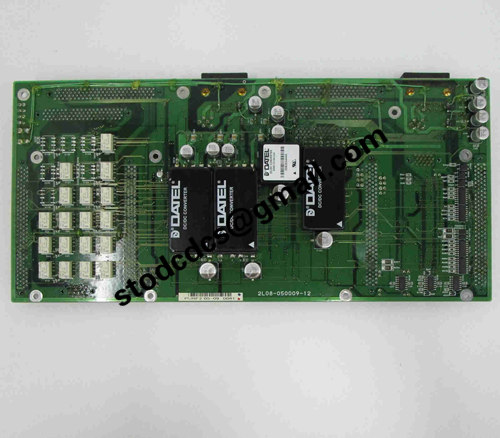

TEL Tokyo Electron 2L81-050009-14 Control Motherboard Card

Brand:TEL Tokyo Electron

Model:2L81-050009-14

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron 2L81-050009-14 Control Motherboard Card

Product manual:

TEL Tokyo Electron 2L81-050009-14 Control Main Board Module

It is the core control unit in TEL semiconductor equipment, responsible for managing and coordinating the various operational logics of the equipment

Process parameters and communication with other sub modules ensure stable and efficient operation of the equipment.

1、 Basic Information

Product Name: Control Motherboard Card/Main Control Board

Product model: 2L81-050009-14

Manufacturer: Tokyo Electron Ltd. (TEL)

Functional Category: Main Controller Board/Logic Processing Module

Installation location: Main control rack or main control chassis inside the equipment control cabinet

2、 Main functions

Equipment operation control

Responsible for executing process control instructions for equipment and scheduling actions of various subsystems.

Automatic adjustment of temperature, pressure, flow rate, vacuum and other parameters for management.

data acquisition and processing

Collect signal data from sensors, digital input boards, analog input boards, etc.

Real time monitoring of equipment status, handling alarms and abnormal events.

communication interface

Communicate with upper level systems (such as factory MES systems) and other control modules, supporting industrial fieldbus protocols.

Realize information exchange and synchronization between modules.

Safety and Interlocking Management

Implement equipment safety interlock logic to ensure operational safety and process stability.

Monitor the status of safety devices such as safety doors, emergency stop buttons, and overload protection.

3、 Typical application areas

Equipment type and function description

Etcher etching equipment controls all key parameters and steps of the etching process

The CVD/ALD deposition equipment is responsible for real-time monitoring and adjustment of the deposition process flow

Track coating and developing equipment management for wafer processing flow, mechanical motion, and process linkage

Transfer system controls the movement, path planning, and safety detection of robotic arms

Product details picture:

2L81-050009-14

More related products:

DSAI130A3BSE018292R1analoginputboard

6ES7312-5BE03-0AB0LogicControllerModule

GE 336A4940CSP16 Interface module

More product recommendations:

NI PCI4451 Data Acquisition Card