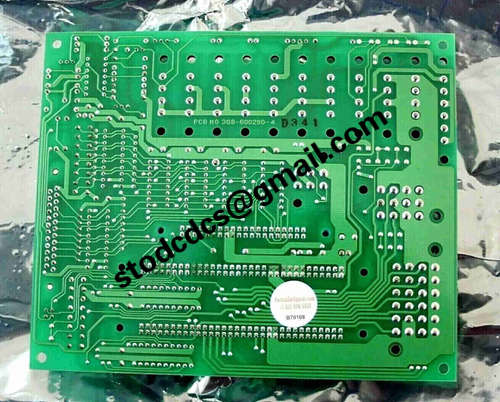

TEL Tokyo Electron 381-600290-7 Control Motherboard Card

Brand:TEL Tokyo Electron

Model:381-600290-7

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron 381-600290-7 Control Motherboard Card

Product manual:

Introduction to TEL Tokyo Electron 381-600290-7 Control Motherboard Card

1、 Basic Information

Product model: 381-600290-7

Product Name: Control Motherboard Card (AD Mother Board)

Manufacturer: Tokyo Electron Ltd. (TEL)

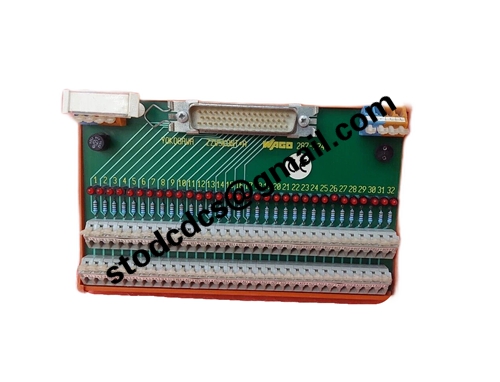

Card type: One of the main control system modules, commonly used in signal processing and equipment management control architecture

2、 Function Description

Signal processing core

Used to receive, convert, and schedule analog or digital signals from various subsystems, it is the hub of device data transmission.

Main control communication bridge

Integrate with the main CPU board, I/O modules, sensor board, etc. to form the core control network of the device.

Equipment Logic Control Platform

Coordinate device execution actions through software defined logic control mechanisms, such as valve switching, temperature control feedback, flow regulation, etc.

3、 Application Fields

Widely used in TEL's semiconductor process equipment, especially etching machines CVD、 Glue coating and developing equipment, etc.

Commonly used in the backbone circuit of control systems, it is a key module for signal distribution and system operation logic.

Alternative cards suitable for regular maintenance, fault replacement, or system upgrades of equipment.

4、 Usage suggestions

Check hardware compatibility: Maintain consistency with the control architecture, backplane signal standards, and voltage specifications of the target device.

Follow the installation process: Ensure replacement is carried out in the event of power failure, and avoid bending or poor contact during the insertion process.

Pre operation testing: After replacement or repair, a power on function test should be conducted to confirm that the control logic is normal.

Regular maintenance inspection: Focus on checking the reliability of connectors, capacitors, resistor components, and PCB solder joints to prevent aging and failure.

Product details picture:

381-600290-7

More related products:

6ES7315-6FF01-0AB0CentralUnitModule

Vibro-meter200-560-101-018IOC4TDiagnosticBoard

Helmholz700-600-CAN01CommunicationModule