TEL Tokyo Electron 381-6400994-2 Controller Module

Brand:TEL Tokyo Electron

Model:381-6400994-2

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron 381-6400994-2 Controller Module

Product manual:

The TEL Tokyo Electron 381-6400994-2 controller module is a specialized electronic control component used in Tokyo Electron semiconductor manufacturing equipment, widely integrated into the core system, responsible for subsystem management and coordination. The following is a detailed introduction to the module (without patterns):

1、 Basic Information

Product model: 381-6400994-2

Product Name: Controller Module

Manufacturer: TEL (Tokyo Electron Limited)

Usage classification: Equipment control module/signal processing unit

System: Applicable to key systems such as CVD, Etch, Coater/Developer for TEL

2、 Main functions and functions

Function category description

The device control core manages the operational status and logical sequence of one or more execution units, such as valves, motors, heaters, sensors, and other subsystems.

Signal acquisition and transmission receive input signals from sensors, encoders, etc., and transmit the processing results to the main control system.

Status monitoring and feedback provide the current execution status (temperature, vacuum, air pressure, position, etc.) for the upper level to determine whether to continue the operation.

Interface bridging enables digital/analog signal conversion and synchronization between the upper computer (main control board) and various execution modules.

3、 Typical application areas

This module is typically installed in the following types of TEL devices:

CVD (Chemical Vapor Deposition) equipment

Control the flow rate of sedimentation gas, power supply, temperature, vacuum chamber, etc.

Etcher (etching equipment)

Manage RF power output, plasma gas flow rate, gas pressure, chamber control, etc.

Coater/Developer

Control the adhesive rotating platform, developing pump system, heating/cooling unit, etc.

Vacuum handling system

Control the process of opening and closing the chamber door, moving the robotic arm, and balancing the air pressure.

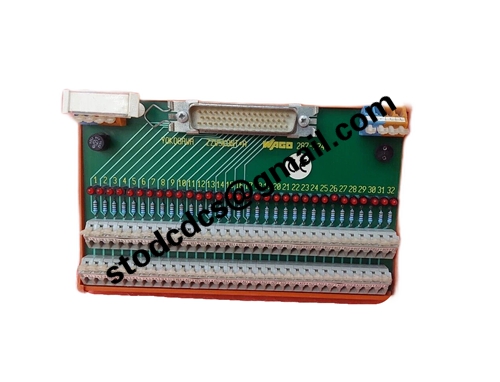

Product details picture:

381-6400994-2

More related products:

FANUC A06B-6120-H108 servo amplifier

6ES7314-1AE02-0AB0CPUController

3BHL000391P0101Lowvoltapowersupplychip