TEL Tokyo Electron 3880-200061-12 Temperature Controller

Brand:TEL Tokyo Electron

Model: 3880-200061-12

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

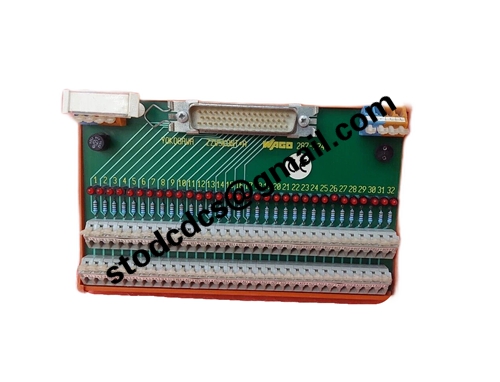

TEL Tokyo Electron 3880-200061-12 Temperature Controller

Product manual:

Tokyo Electron (TEL) 3880-200061-12 Temperature Controller - Product Application Field Detailed Explanation

1. Precise temperature control in semiconductor manufacturing equipment

Core function: This temperature controller is designed specifically for semiconductor manufacturing equipment,

Accurately adjust the temperature of the process environment to ensure temperature stability in key process steps such as photolithography, etching, and deposition.

Significance: Small fluctuations in temperature can directly affect product yield and consistency,

This controller effectively ensures the stability of process parameters.

Typical applications: Temperature control systems for key equipment such as wafer processing modules, thin film deposition equipment, and lithography machines.

2. Temperature management in automated production lines

Real time monitoring: Real time collection and adjustment of equipment temperature data to ensure that the temperature is within the set range,

Avoid production interruptions caused by abnormal temperature.

Efficient operation: Helps automated production lines achieve continuous and stable operations, reducing equipment failure rates.

Application scenario: Automated handling system and auxiliary equipment for semiconductor wafer manufacturing.

3. Important components of equipment thermal management system

Heat dissipation regulation: By precise temperature control, equipment overheating is prevented, ensuring the normal operation of internal electronic components and mechanical parts.

Improve lifespan: Reasonably control equipment temperature to effectively extend the overall service life of the equipment.

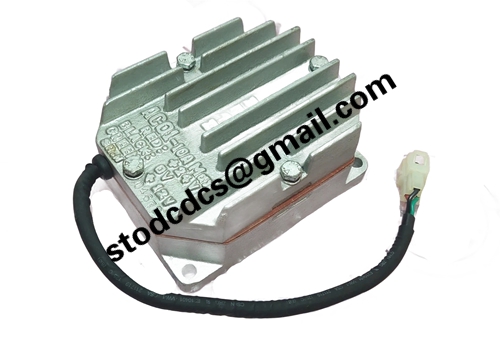

Typical equipment: high-power drive unit, laser system, induction heating module, etc.

4. Temperature stability guarantee during high-precision manufacturing process

Ensure product consistency: precise temperature control to avoid thermal expansion

The dimensional changes caused by temperature differences ensure high precision and consistency in product processing.

Improve yield: A stable temperature environment reduces defect rates, enhances overall production efficiency and product quality.

Application areas: high-end microelectronics manufacturing and precision instrument manufacturing.

Product details picture:

3880-200061-12

More related products:

500CIM051MRB150077R1BCommunicationinterfacemodule

GE 336A4940CSP1 Analog input module

500BIO011MRB150005R1Jinvertercontrolunit

More product recommendations:

Siemens 6ES7291-8GC00-0XA0 cartridge