TEL Tokyo Electron 3M87-024252-23 Controller Module

Brand:TEL Tokyo Electron

Model:3M87-024252-23

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

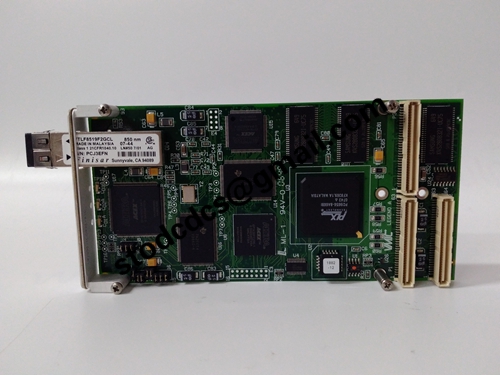

TEL Tokyo Electron 3M87-024252-23 Controller Module

Product manual:

TEL Tokyo Electron 3M87-024252-23 Controller Module

It is a control core unit module applied in semiconductor manufacturing equipment,

Mainly used for unified management of various functional modules of equipment (such as gas system, temperature control system, motion mechanism, etc.)

Logical operations and control instruction issuance are key components in achieving automated precision process control.

1、 Basic Information

Product model: 3M87-024252-23

Product Name: Controller Module

Manufacturer: Tokyo Electron Ltd. (TEL)

Module Type: Embedded Control System Components/Process Control Cards

Applicable platforms: May be used for TEL coating/developer, CVD, Etcher, or ALD systems, etc.

2、 Core functions

Process control

Run TEL device control logic to manage the start stop, switching, timing, synchronization, etc. of each process step.

Peripheral module coordination

Collaborate with I/O board, air valve control board, driver module, temperature control board, etc. to execute logical action control.

Equipment status monitoring and feedback

Real time collection of the operating status of each subsystem, and making judgments, feedback, or alarms based on set conditions.

Communicate with the main system

Interact data with the host or upper system through system buses such as TEL dedicated buses, Ethernet, CAN, etc.

Embedded program running

Internally, it may be equipped with embedded processors and fixed software for executing specific process control programs.

3、 Typical application areas

Coater/Developer system

Control the rhythm and condition judgment of wafer transfer, rotation, coating, and development steps.

CVD/ALD equipment

Manage the switching of reaction gases, temperature settings, and the rhythm logic of the deposition process.

Plasma etching system

Control key parameters such as plasma source on/off, RF power status, chamber pressure and airflow regulation.

Rear packaging/cleaning module

Implement fluid/solution control, pump valve switching, circulation time control, waste liquid discharge and other operational management.

Product details picture:

3M87-024252-23

More related products:

YOKOGAWACP451-50ControlmoduleCPU

6ES7315-2AF03-0AB0processormodule

YOKOGAWANFAI841-S00Input/outputmodule

More product recommendations:

RADISYS EXM-HDEXM-MX Memory Module