TEL Tokyo Electron CS1B85-372049-W1 motor impact module

Brand:TEL Tokyo Electron

Model:CS1B85-372049-W1

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron CS1B85-372049-W1 motor impact module

Product manual:

Tokyo Electron (TEL) CS1B85-372049-W1 Motor Shock Module - Product Application Field Detailed Explanation

1. Wafer transfer system in semiconductor manufacturing equipment

Key role: This module plays a crucial role in the wafer transfer process,

Responsible for adjusting the impact force during motor start and stop to ensure smooth wafer movement.

Application value: To prevent wafer displacement, damage, or positional deviation caused by impact or vibration during transmission,

Ensure the integrity of the wafer and the stability of subsequent processes.

Typical scenarios: wafer handling robots, conveyor belt start/stop control, shock absorption optimization of conveying mechanisms, etc.

2. Automated mechanical motion control

Dynamic adjustment: This module controls the motor impact,

Optimize the start and stop processes of robotic arms or conveyor systems.

Effect improvement: effectively reducing the vibration and impact of mechanical systems,

Improve the smooth operation and repeated positioning accuracy of the equipment.

Application examples: Automated loaders, precision robotic arms, motor-driven conveyors, etc.

3. Equipment vibration suppression and performance optimization

Vibration buffering: By precisely controlling the impact force of the motor, the vibration caused by mechanical impact is reduced,

Protect sensitive components inside the equipment.

Extend lifespan: Effectively avoid mechanical fatigue and damage caused by frequent impacts, and extend the service life of equipment.

Easy maintenance: reduce failure rate, minimize maintenance frequency and downtime, and improve production line utilization rate.

4. High precision positioning system support

Smooth operation: Ensure smooth and stable operation during wafer loading, unloading, and handling to avoid positioning errors.

Process assurance: Stable positioning supports high-precision process execution, improving product yield.

Application environment: In situations where high-precision mechanical positioning is required, such as microfabrication equipment, lithography machines, etching equipment, etc.

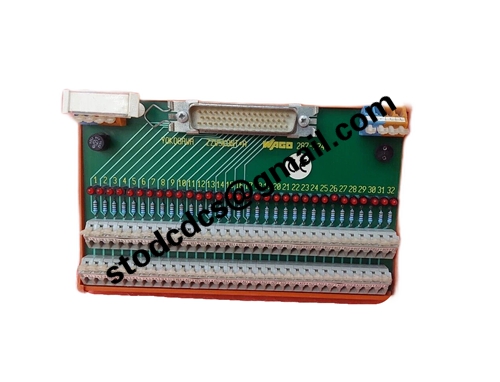

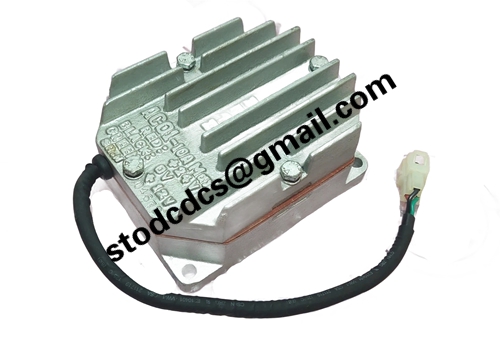

Product details picture:

CS1B85-372049-W1

More related products:

500CIM051MRB150077R1BCommunicationinterfacemodule

GE 336A4940CSP1 Analog input module

More product recommendations:

LAM 810-800081-016 CPU motherb