TEL Tokyo Electron E249-000003-13 Screen Monitor

Brand:TEL Tokyo Electron

Model:E249-000003-13

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron E249-000003-13 Screen Monitor

Product manual:

TEL Tokyo Electron E249-000003-13 Monitor Display Unit is an industrial grade display module specifically designed for TEL semiconductor equipment,

Mainly used for human-machine interface (HMI) operation, system status monitoring, alarm display, and process data visualization.

It is usually used as a part of the console or equipment panel, providing an interaction and control platform for engineers or operators.

1、 Basic Information

Product Name: Screen Monitor/Display Unit

Product model: E249-000003-13

Manufacturer: Tokyo Electron Ltd. (TEL)

Product type: Industrial Monitor

Applicable equipment: Etching machines, CVD machines, cleaning machines, Track systems, etc. for TEL

2、 Main functions

Process monitoring display

Real time display of equipment process parameters (temperature, pressure, flow rate, etc.);

Display key information such as cavity status, process progress, equipment alarms, etc.

Operation interface support

Used to display human-machine interface (HMI), operators can control equipment through touch or button operation;

Support menu switching, log query, recipe setting and other functions.

Alarm and Reminder

Display current system alarm, fault information, and warning codes;

Guide users to quickly troubleshoot and restore production.

Communication and remote management interface

Support communication with TEL main control system or PLC, real-time synchronization of data;

Compatible with TEL dedicated software interface or embedded control platform.

3、 Typical application areas

Etcher (etching equipment)

Monitor chamber air pressure, power load, RF parameters, and chamber opening and closing status.

CVD/ALD (Chemical Vapor Deposition Equipment)

Display temperature curve, flow rate setting, film thickness control, and system readiness status.

Wet Station (cleaning equipment)

Display real-time parameters such as cleaning process, medication status, pH/temperature changes, etc.

Track System (photoresist developing equipment)

Control the coating rotation, baking temperature, development time, and wafer path.

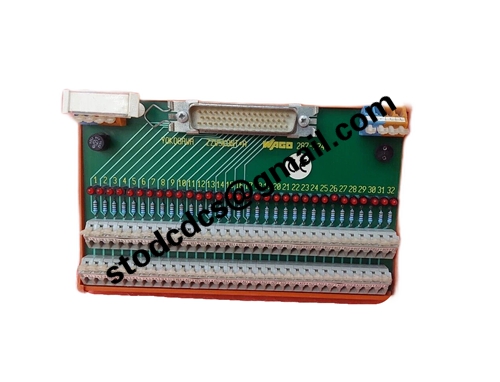

Product details picture:

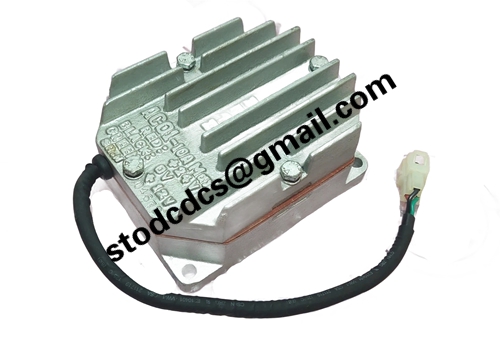

More related products:

DS200DCFBG1BJB Circuit Board Component

DS200FSAAG2ABA processor board

61430001-XGindustrialcontrolequipmentmodul