TEL Tokyo Electron MR-MC01-S100 Controller Module

Brand:TEL Tokyo Electron

Model:MR-MC01-S100

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

TEL Tokyo Electron MR-MC01-S100 Controller Module

Product manual:

TEL Tokyo Electron MR-MC01-S100 Controller Module

(Controller Module)

Product Function Introduction:

MR-MC01-S100 controller module

It is a core component of TEL (Tokyo Electron) equipment specifically designed for high-precision motion control or automated process control.

This module typically integrates a microprocessor, I/O control interface, communication interface, and motor control logic,

It is the control core that enables precise execution of equipment actions.

The main functions include:

Control the operation and positioning of stepper motors or servo motors

Realize multi axis linkage, speed control, and acceleration/deceleration curve generation

Receive action instructions from the upper system, perform logical processing and feedback

Support sensor input and limit detection to ensure safe operation of equipment

Provide communication capabilities with the main control system or human-machine interface (such as RS-232/485, Ethernet, CAN, etc.)

Main application areas:

1. Control of wafer handling and positioning system

Manage precise movements of handling arms, alignment platforms, and other components in subsystems such as EFEM, Transfer Module, and Aligner

Execute the logic of the wafer transport path from FOUP → Load Port → Process Chamber

2. Multi axis motor control

Control the coordinated motion of multiple execution axes (X, Y, Z, or θ axis) to achieve precise mechanical structure control

Parameters such as speed, acceleration, target position, zeroing, etc. can be set

3. Control of components in vacuum or gas systems

Control the linkage of vacuum valves, gas valves, and electromagnetic mechanisms to achieve process interlocking logic

Accurately control time, sequence, and action amplitude during the processing

4. Logical control of process flow

Coordinate actions in step-by-step machining processes such as preheating, pressurization, plasma activation, etc

Manage the start stop and status feedback of actuators and sensing components

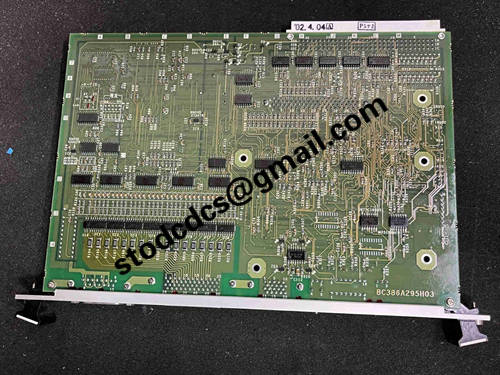

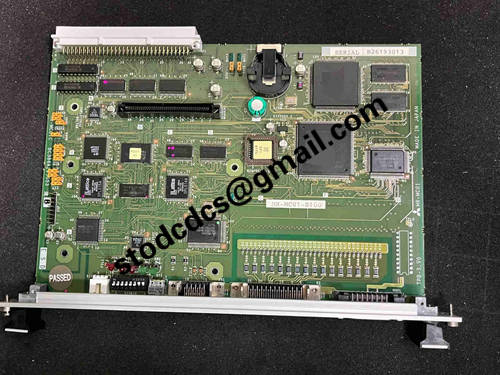

Product details picture:

MR-MC01-S100

More related products:

216EA61BHESG448230R1/Gdigitalinputmodule

531X305NTBAPG1 driver control terminal board

More product recommendations:

ASEA DSQC100 connector backplane