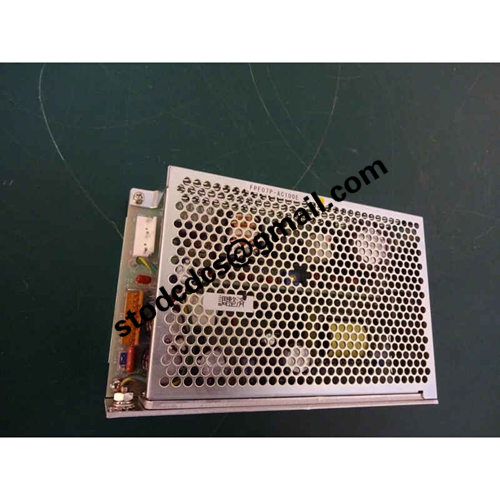

Tokyo Electron FPF07P-AC100E Ultrasonic Device

Brand:TEL Tokyo Electron

Model:FPF07P-AC100E

Product status: New/used

Shipping place: Xiamen, China

Warranty: 365 days

Structural form: Other (specific form may vary depending on application)

Please contact Yvonne for quotation, thank you!

Details

Tokyo Electron FPF07P-AC100E Ultrasonic Device

Product manual:

Tokyo Electron FPF07P-AC100E Ultrasonic Transformer Unit

It is a key cleaning component integrated into TEL wet cleaning or developing equipment,

Mainly used for non-contact, high-precision cleaning of wafer surfaces through ultrasonic cavitation effect.

This model is suitable for cleaning processes in the front or middle stages of wafers, which can significantly improve particle removal efficiency and yield.

1、 Basic Product Information

Product Name: Ultrasonic cleaner/Ultrasonic cleaning head

Product model: FPF07P-AC100E

Manufacturer: Tokyo Electron Ltd. (TEL)

Working voltage: AC 100V (inferred from the model)

Applicable location: in modules such as wafer cleaning chamber, developing tank, and delamination tank

2、 Core functions

Efficient particle removal

By high-frequency vibration, tiny cavitation bubbles are formed in the liquid to remove pollutants such as particles, residual glue, and metal ions from the wafer surface;

Effectively used for removing fine particles below 0.1 μ m.

Non contact cleaning

Not causing physical contact with the wafer, suitable for device structures that are extremely sensitive to surface stress in advanced processes (FinFET, EUV).

Support chemical solution cleaning

Can be combined with deionized water (DIW), ozone water SC-1、SC-2、 Dilute hydrofluoric acid and other cleaning solutions for use.

Security control mechanism

Integrated linkage functions such as temperature control, liquid level detection, and power protection;

Support communication with the main device, automatic start stop and alarm feedback.

3、 Typical application areas

Purpose of use during the application process stage

After photolithography, develop and clean to remove residual adhesive and development by-products

After etching, clean to remove metal particles and residual oxide deposits

Clean and remove polishing solution residue after CMP to prevent wafer scratches

Wet bench wet equipment as an integrated cleaning unit at the bottom or side of the liquid tank

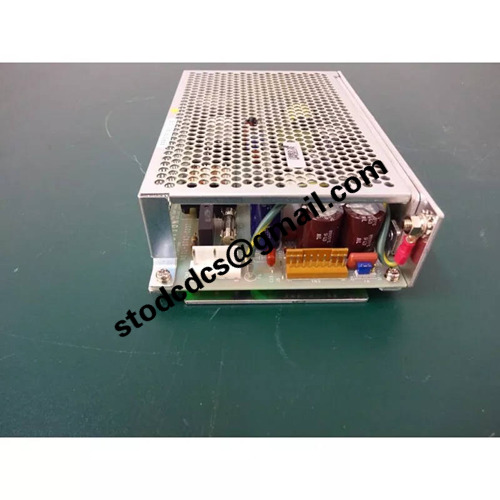

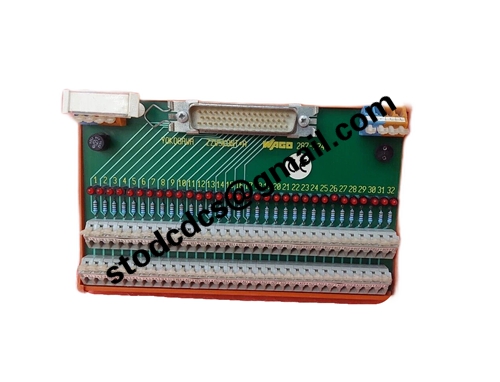

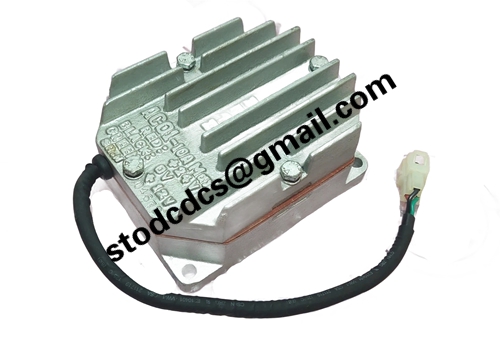

Product details picture:

FPF07P-AC100E

More related products:

6ES7312-5BE03-0AB0LogicControllerModule

GE 336A4940CSP16 Interface module