Details

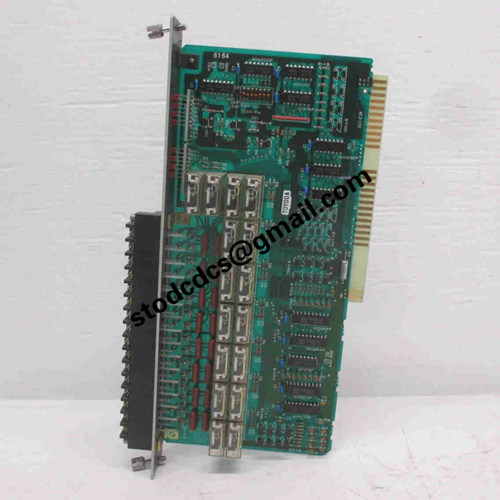

TOYOTA TP-1246-2 Controller Board

Product manual:

product overview

The TOYOTA TP-1246-2 controller board is a core control module designed specifically for Toyota's industrial automation systems. It has high-performance processing capabilities and rich input-output interfaces, and is widely used in production line control, robot systems, and automation equipment to achieve precise and efficient process control.

Product application areas

Automotive Manufacturing Automation

Automated equipment for controlling key processes such as stamping, welding, painting, and final assembly.

Realize multi station coordination and real-time monitoring to improve production efficiency and product quality.

industrial robot control

Drive the robot to complete tasks such as welding, handling, and assembly, ensuring precise and reliable movements.

Support multi axis linkage to meet the control requirements of complex motion paths.

Automatic detection and quality control

Collect sensor data, perform automatic detection process judgment and feedback.

Collaborate with visual inspection systems and other equipment to enhance the level of quality monitoring.

Logistics and Transportation System

Control conveyor belts, sorting robotic arms, and automatic stacking equipment to ensure smooth logistics.

Realize automatic identification, allocation, and tracking of materials.

Non standard automation equipment

Automation units suitable for customized processes, such as precision assembly, testing equipment, etc.

Support flexible programming and system expansion to meet diverse production needs.

Intelligent Manufacturing and Digitalization of Factories

As the core of production control, achieve equipment networking and data integration.

Support integration with MES, SCADA and other systems to promote the upgrade of intelligent manufacturing.

Product details picture:

TP-1246-2

More related products:

531X307LTBAKG1 power interface card module

531X309SPCAJG1 signal processing board