Details

WOODWARD 5464-658 Digital Speed Sensor

Product manual:

WOODWARD 5464-658 digital speed sensor is a high-performance speed detection device designed specifically for industrial engine control systems,

Mainly used for WOODWARD controllers (such as EPG, 2301A/Digital series, 723, 505, easyYgen, etc.)

1、 Product Overview

Model: WOODWARD 5464-658

2、 Main functions

High precision speed measurement: Provides pulse signal feedback and supports high-resolution RPM detection

Digital signal output: compatible with WOODWARD controllers, typically output in TTL, differential, or frequency signal format

Strong anti-interference ability: suitable for industrial electromagnetic environment, with good noise resistance design

High reliability: capable of long-term stable operation in high temperature, high humidity, and high vibration environments

3、 Technical parameters (typical, please refer to the model data sheet for details)

Parameter Description

The input power supply is usually 8-32 VDC (powered by the controller)

Output signal pulse output (digital frequency signal, TTL or differential square wave)

Speed measurement range: 0-20000 RPM (depending on the installation position of the sensor and the number of gear teeth)

Detecting magnetic gears or coding disks (usually requiring the use of magnetic steel gears)

Install interface thread type or flange type (depending on version)

Working temperature -40 ° C to+105 ° C (industrial grade)

Protection level IP65 or above (depending on the enclosure sealing structure)

4、 Typical application scenarios

Cooperate with WOODWARD speed controllers or control systems (such as 723PLUS, 505, 2301D) to achieve:

Engine speed closed-loop control

Parallel synchronization judgment

Load distribution control

Coordinated control of main and auxiliary machines in power systems

Turbine/gas turbine speed control system with high reliability requirements

5、 Installation and usage suggestions

Gear matching: It is recommended to use 60 tooth or 100 tooth metal magnetic gears to improve speed measurement accuracy;

Environmental protection: Avoid installation near strong magnetic fields, welding, and high temperature sources to ensure measurement accuracy.

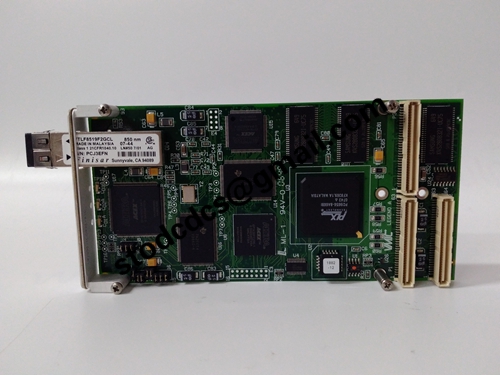

Product details picture:

More related products:

Schneider 140CP43412A Controller Module

Schneider 140CPS11100 Analog Input Modul

KOLLMORGEN CP310250 PRD-P310250Z-55 serv

More product recommendations:

FANUC A06B-6120-H108 servo amplifier